How to open Western Digital Helium Drives

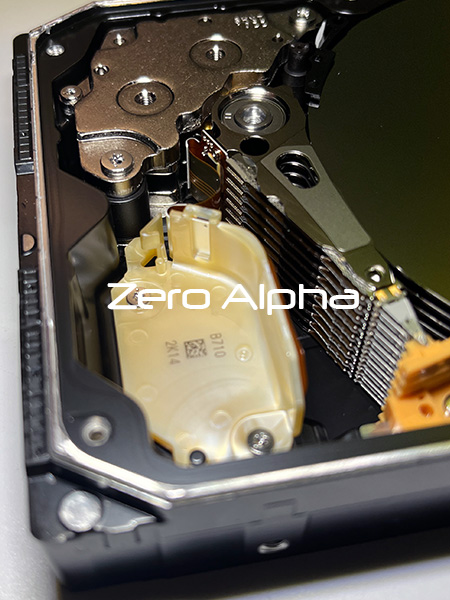

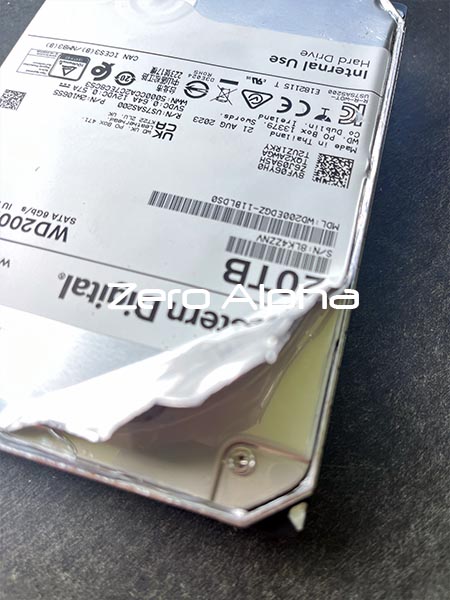

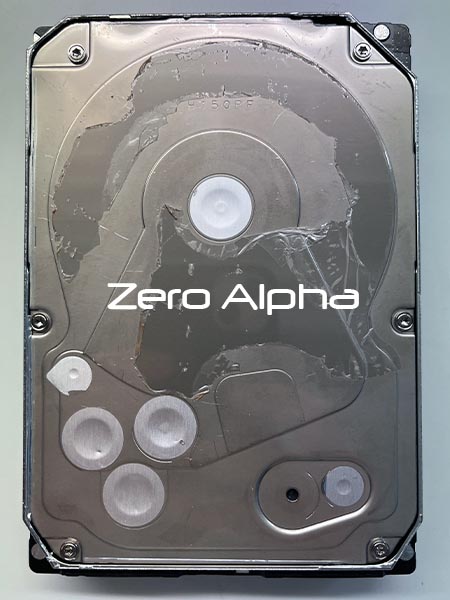

Western Digital high capacity hard drives have an extra 0.5mm aluminium laser welded sealed layer on them than previous generation drives. The helium atmosphere of these hard drives makes it more difficult to service for data recovery. However if your skilled enough they are still easy to open and service for data recovery.

Step 1: Cut the 0.5mm aluminium welded seam

Step 2: Be careful to peal and lift the cover as it has a double sided sticker to old it in place.

Helium Inside

Western Digital, like other major hard drive manufacturers, has introduced helium-filled hard drives for several important reasons. Helium-filled drives offer several advantages over traditional air-filled drives, which have been the standard for many years. Here are some key reasons why Western Digital and other manufacturers have adopted helium-filled drives:

-

Reduced Air Resistance: In a traditional air-filled hard drive, the spinning platters experience air resistance, which can slow down the rotation and lead to increased power consumption and heat generation. Helium is much less dense than air, so it significantly reduces air resistance. This allows the platters to spin more freely, resulting in lower power consumption and improved performance.

-

Increased Data Density: Helium-filled drives allow manufacturers to pack more platters and read/write heads into the same physical space. This increased data density can lead to higher storage capacities within standard form factors like 3.5-inch drives, making them ideal for data centers and enterprise applications where storage space is at a premium.

-

Lower Power Consumption: Reduced air resistance means less power is required to spin the platters and move the read/write heads. This results in lower power consumption, which is particularly beneficial for large-scale data centers looking to reduce energy costs and improve overall efficiency.

-

Improved Cooling: Helium dissipates heat more effectively than air, which helps maintain a more stable operating temperature inside the drive. This can lead to increased reliability and longer lifespan for the drive components.

-

Lower Vibrations and Noise: Helium-filled drives often produce less vibration and acoustic noise compared to traditional drives. This makes them suitable for applications where noise and vibration can be a concern, such as audio recording or high-density storage arrays.

-

Enhanced Reliability: Helium-filled drives can offer increased reliability due to their reduced power consumption, improved cooling, and the reduced wear and tear on drive components. This is essential for critical applications in data centers where drive failures can lead to data loss and service disruptions.

-

Sealed Design: Helium-filled drives are hermetically sealed to keep the helium inside and prevent air from entering. This design minimizes the risk of contamination and moisture damage, further enhancing the drive's durability.

While helium-filled drives offer numerous benefits, they also tend to be more expensive to manufacture than traditional air-filled drives, primarily due to the need for specialized sealing and manufacturing processes. However, the advantages in terms of performance, reliability, and data density often outweigh the higher production costs, making helium-filled drives an attractive option for data centers and other high-capacity storage environments.