Saving Your Data: Recovery from a Damaged Western Digital PCB with USB-C Interface

Picture this: your precious Western Digital (WD) hard drive, equipped with a USB-C interface, has served you well over the years. But then, disaster strikes. Perhaps the drive was dropped, or something heavy was placed on it, and now, the Printed Circuit Board (PCB) is cracked and damaged. Now, the hard drive is unresponsive, and it feels like all of your data might be lost forever.

However, even in such a dire situation, hope is far from lost. Welcome to the world of Zero Alpha, where we specialize in retrieving your invaluable data from such predicaments.

At the heart of this mission is a technical process requiring precision and specialized knowledge. The PCB is an essential component of a hard drive, containing crucial firmware for the proper functioning of the drive. When it is damaged, the drive can no longer communicate with your computer, making data inaccessible.

One of the biggest challenges here is the built-in encryption that comes with WD drives. While this feature enhances data security, it makes the recovery process more complex. However, our skilled technicians at Zero Alpha are adept at handling this encryption and can successfully extract data from these drives.

Our data recovery process involves several techniques. Micro soldering, for instance, is a skillful task our experts perform to repair the broken traces on the PCB. This method involves using a microscope and a precision soldering tool to fix minute details, often thinner than a human hair.

If the PCB is beyond repair, we employ a chip swapping procedure to a donor PCB. This involves moving the BIOS chip containing the drive's unique adaptive data from the damaged PCB to a new, identical one.

In cases where the chips on the PCB have become detached or their solder has cracked, we use a technique known as Ball Grid Array (BGA) reballing. This involves removing the chip, cleaning off the old solder, applying new solder balls, and then reattaching the chip to the PCB.

Through the combination of these techniques, Zero Alpha can often successfully recover data from damaged Western Digital hard drives, even those with a cracked or damaged PCB.

In conclusion, if you find yourself with a damaged Western Digital PCB with a USB-C interface, don't despair. Contact Zero Alpha, and let our team of professionals use their expertise to bring your data back from the brink. Your digital treasures may not be as lost as you think.

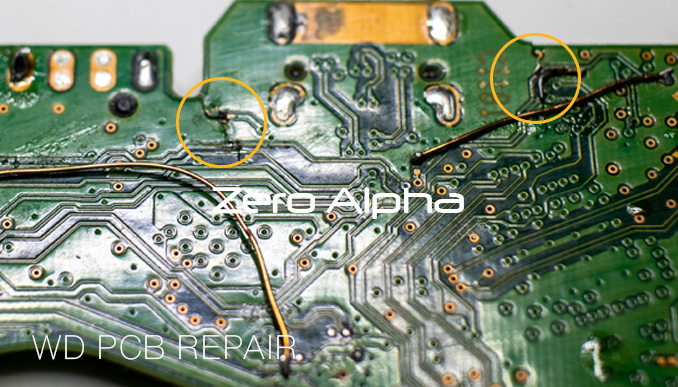

Case Example WD 2060-810033-001 PCB

The orange circles highlight where the cracks break through pcb wiring. Trace wires that could be soldered back together were done carefully while other trace wires were reconnected with external wiring.

We did have success with accessing the drive via the main controller units SATA interface but this model has hidden encryption keys only accessible via the USB-C interface. There is an external rom chip which only contains the wd firmware and not the self encryption drive keys (SED).

The USB-C ASMEDIA chip which controls usb connection unfortunately does not contain the encryption keys needed to decrypt this drive.

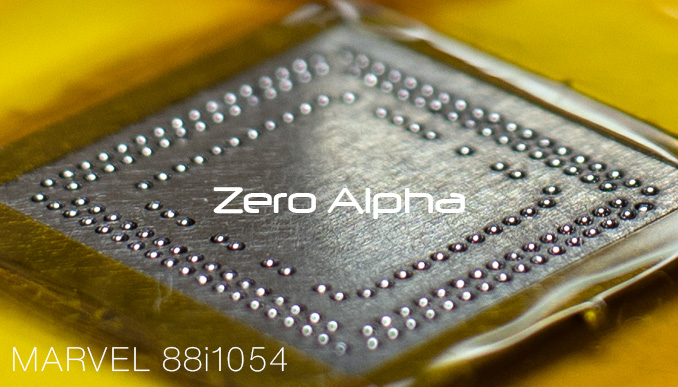

We had to swap the main cpu chip to a new donor pcb board. We use 0.3mm to 0.35mm max size solder balls were used to reball the Marvel 88i1054 cpu chip. This is the same chip that stores the individual unique encryption keys used to unlock the data

A close up the the marvel 88i1054 reballing stencil. This work is very delicate and needs to be performed with extreme care and special electronics microscope in tandem use with a solder rework station.